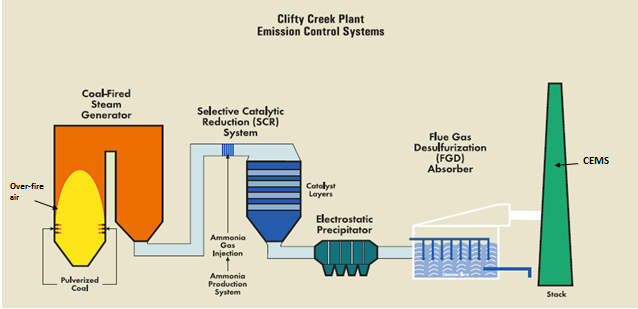

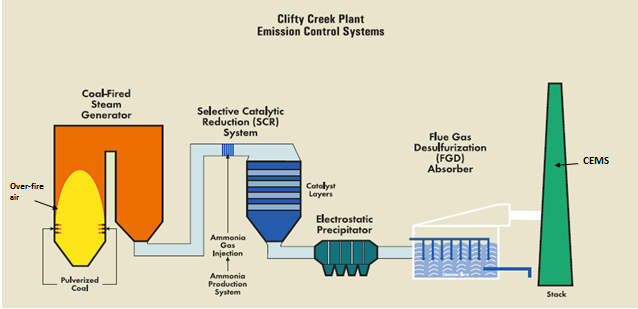

Protecting the Environment - Clifty Creek

Clifty Creek Station meets or exceeds the environmental

standards set by state and federal regulations. Originally built

for $158 million, Clifty Creek has invested more than $1 billion

on environmental upgrades since its original construction.

Plant employees take great pride in providing low-cost

electricity while protecting air and water quality, recycling of

materials, and maintaining an exemplary record of public and

workplace safety.

- In the mid 1990's, almost $80 million was invested to

modify the coal yard and each of its six boilers to burn

low-sulfur Western coal.

- Overfire air systems reduce nitrogen oxide (NOx) emissions

by up to 60 percent. An overfire air design injects air

above the burning zone in the boiler to enhance combustion.

This infusion of air limits the formation of nitrogen dioxide,

thereby reducing the formation of NOx, a percursor to ozone.

Overfire air was installed in the late 1990's at a cost of

approximately $4 million.

- Selective catalytic reduction (SCR) systems and an ammonia

production facility operate year round on five of the six units

to reduce nitrogen oxide (NOx) emissions up to 90 percent.

Ammonia injected into the plant's exhaust gases causes a chemical

reaction as the gases pass over a catalyst, converting the nitrogen

oxide to harmless atmospheric nitrogen and water. The ammonia

is manufactured on an as-needed basis through a unique process

that coverts urea (commonly used as a fertilizer) into ammonia.

Total capital investment for the entire project was approximately

$164 million. The SCR system began operation in 2003, a full

year earlier than required.

- Electrostatic precipitators remove more than 99 percent

of all fly ash particles produced by coal combustion.

In precipitators, fly ash from burning coal passes through

electrically-charged plates, which pull the ash particles out of

the exhaust gas stream. The original precipitators were

replaced at a cost of $105 million in the late 1970's.

- In 2013, Jet Bubbling Reactor (JBR) scrubbers came online, with

nearly $670 million invested in the project. JBR systems use

a limestone-water slurry to remove up to 98 percent of the sulfur

dioxide (SO2) in the flue gas. The resulting by-product of

this JBR process is gypsum, which can be used as an agricultural

soil amender, or safely managed in a landfill.

- Automated Continuous Emission Monitoring Systems (CEMS) installed

in the plant stacks monitor stack gas emissions. These highly

accurate systems help ensure compliance with clean air requirements

for SO2 and NOx emissions and opacity.

- A portion of the plant's fly ash is sold and used as an additive in concrete.